Data continuity across the value chain: the right data at the right time

Smart everythingIt's really hard to design products by focus groups. A lot of times, people don't know what they want until you show it to them.

Developing appealing new products and successfully launching them to market relies on the expertise of specialists who use the appropriate development tools and processes. New product introduction (NPI) necessitates a blend of innovation, efficient business operations, and technical and financial change management traceability.

Enabling new product development (NPD) involves disciplined and goal-oriented planning that aims to converge towards commercialization and predictable revenue expectations. This includes increasing certainty, analysis, and documentation as the product release date approaches.

Xlifecycle Ltd offers digital continuity and business transformation consulting services that help organizations optimize their digital strategies in order to:

ADAPT to change

By discovering and aligning requirements from new technologies, products and market attributes, customer expectations, to sustain competitive advantage while continuously managing total cost of ownership.

ADOPT digital continuity solutions

By aligning people, data, process and technology across the business change roadmap, managing complexity and cross-functional stakeholders, defining critical success factors, from RFQ definition to project service transition, including vendor & partner delivery and relationship management.

TRANSFORM operating models

By defining fit-for-purpose operating practices and new organizational structures to maximize value from digitization and IT modernization, aligning skills and talents to education requirements to enable effective deployment and operational transition to minimize time-to-value realization.

Successful digital transformation requires more than just implementing technology; it involves aligning the business across multiple perspectives, from people to data, processes, tools, and technologies. Unless there is a cohesive approach across all pillars, little or no transformation will occur.

Cultural alignment is vital for digital transformation to succeed, so the first concern should be getting people on board. Prioritizing business transformation initiatives requires continuous capability development, digital roadmaps, and a robust understanding of how much change the business can handle within a given period of time.

Towards smart everything: from smart products to smart operations

Lifecycle of thingsAmid the rapid pace of technological advancements, businesses face both opportunities and challenges. Companies are increasingly leveraging technology to enhance products, services, and operations, striving for greater efficiency and effectiveness across the entire lifecycle.

Elements such as products, applications, talent, and data progress through various lifecycle stages simultaneously, evolving iteratively and interdependently. This interconnected evolution is reshaping the way businesses approach their digital strategies, creating a dynamic and responsive ecosystem.

Digital transformation involves leveraging digital technology to reshape business operations, particularly in customer interaction and value creation across the supply chain. It goes beyond traditional IT, encompassing a broader business transformation.

Successful digital transformation requires challenging existing practices and adopting new methods, operating models, and technologies tailored to each organization's culture, context, and industry maturity. Establishing a universal definition of digital maturity is complex due to varying factors, including culture, context, and organizational maturity. As a result, companies must continuously assess and enhance their digital maturity levels, adapting to their unique characteristics and circumstances.

ASSESS

Is this a technical upgrade, a business transformation, or both?

ENGAGE

Are the teams engaged and committed to the change?

EXTEND

Who will benefit from the change and how will value be realized?

FOCUS

Are priorities aligned across the business and support functions?

MEASURE

How to track and measure progress with business owners and change leads?

EVOLVE

Is the organization ready to operate effectively once the change is implemented?

SCALE

What are the next steps in the transformation roadmap?

LEARN

What are the lessons learned to feed into next improvement steps?

IMPROVE

How is the business run, what is the operational governance, is it effective?

TRANSITION

How to transition business changes to the new operating model?

Clear communication of the digital strategy across the organization, especially to the leadership team, is crucial for driving digital transformation. The language should be tailored to resonate with the leadership team to ensure their buy-in and support.

Without their understanding and endorsement, securing the necessary resources and commitment for meaningful progress in the digital journey becomes difficult. As a result, the leadership team should play an active role in shaping the strategy, setting the direction, and leading the organization toward its digital future, rather than remaining passive observers.

Organizations today face common pressures such as maintaining profitability, staying competitive, meeting customer expectations, ensuring sustainability, complying with regulations, and adapting to technological changes. These pressures drive the need for digital transformation.

With the rise of new technologies, organizations can now create and align new business models to improve operations, both internally and across their value networks. Understanding why companies pursue digital transformation, their operational context, and strategies for change is essential.

The value chain consists of internal activities like logistics, operations, marketing, and services, while the value system extends to suppliers and customers. By considering both, organizations can identify opportunities to leverage digital technologies, create value for customers, and foster innovation in their industry.

1. ASSESS

Is this a technical upgrade, new capability or business transformation, or both?

1. ASSESS

How is change embraced? What is the training and communication culture? What are the anticipated hindrances? What mitigations are required?

2. ENGAGE

Are the relevant teams and sponsors engaged and committed to the change?

2. ENGAGE

How will the change be implemented? Who will drive what? Who are the supporters and detractors? How to influence and manage expectations?

3. EXTEND

Who will be affected by the change, how will value be realized and when?

3. EXTEND

How will continuous benefit realization be tracked? How can value be maximized across the enterprise? What is the time to value creation and delivery velocity?

4. FOCUS

How are priorities aligned across the core business and support functions?

4. FOCUS

How is the scope controlled across technical and business dependencies? How well is the deployment plan and benefit realization managed?

5. MEASURE

How to track and measure progress with business owners and change leads?

5. MEASURE

What are the CSFs and KPIs to define and track progress towards successful change? Who are the business owners, data custodians, and champions?

6. EVOLVE

Is the organization ready to operate effectively once the change is rolled out?

6. EVOLVE

Who are the early adopters? How will the change agents operate? What decisions will be required when? How will production impacts be handled?

7. SCALE

What are the next steps in the change and digitalization combined roadmap?

7. SCALE

Does the deployment strategy require refinement? Have business priorities changed? Which capability and / or business function will be deployed next?

8. LEARN

What are the lessons learned to feed into next change or improvement steps?

8. LEARN

What worked well and not so well? Was the organization ready and able to adapt? What is likely to happened next time, and are risks mitigated and how?

9. IMPROVE

How is the business run, what is the operational governance, is it effective?

9. IMPROVE

Once new solution elements are implemented, how are business benefits adjusted? How will subsequent continuous improvement actions be tracked?

10. TRANSITION

How to effectively drive business changes per the new operating model?

10. TRANSITION

How to integrate the new platform with existing infrastructure and processes? How users be trained and equipped to use the new solution effectively?

Frameworks like the one outlined above provide organizations with a structured method for managing the complexities of digital transformation. They help define new operating models while considering both internal and external changes.

By following the roadmap and guidelines set by these frameworks, organizations can confidently and efficiently pursue their digital transformation goals. This includes adopting new technologies, optimizing processes, and building capabilities to enhance competitiveness and meet customer demands.

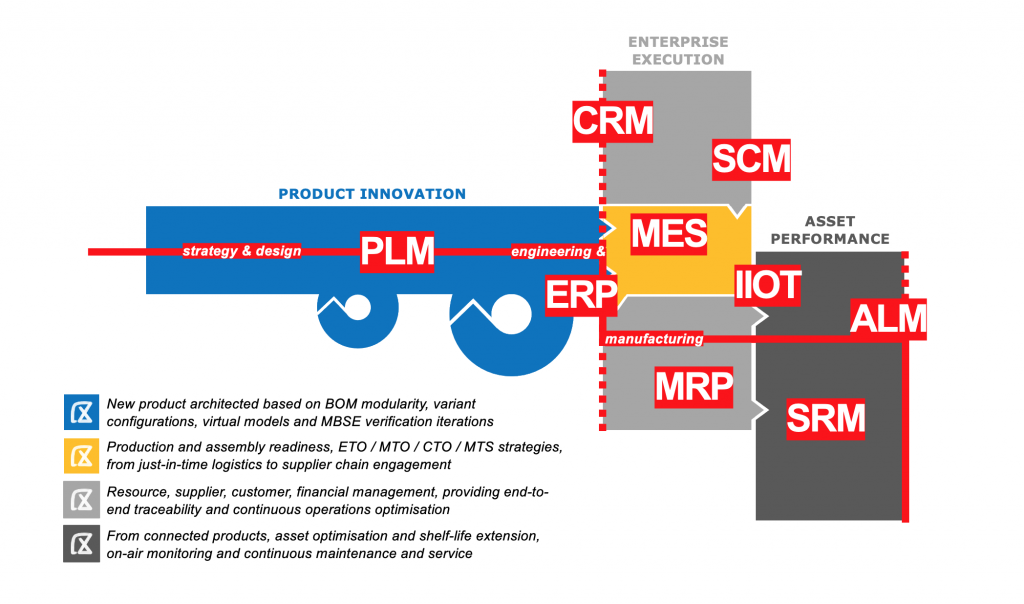

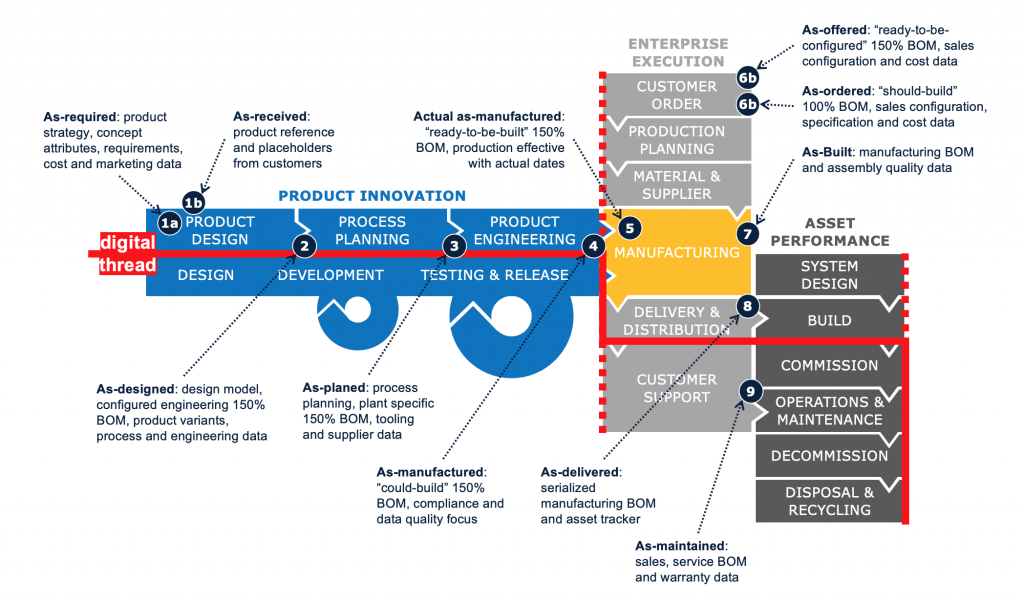

Digital Thread: unlocking data connectivity across enterprise capabilities

Bills of Materials (BOMs) are more than just a tool—they are the backbone of the product lifecycle. Acting as the bridge between functions like product innovation, enterprise execution, and asset performance, BOMs drive efficiencies and enable smooth data flow across departments—from concept development to manufacturing and multi-tier product costing. They serve as the central hub for managing product data, ensuring it informs every aspect of the business and transforms insights into actionable outcomes.

When BOMs are aligned with the product data lifecycle, organizations unlock exceptional operational efficiency and foster cross-functional collaboration. This synergy boosts the speed, agility, and precision necessary to meet market demands and maintain competitiveness.

Leveraging BOMs to streamline operations is not just a best practice—it’s a strategic imperative. The key to operational excellence lies in integrating data across functions, creating a unified enterprise capable of innovation and execution at scale.

To achieve comprehensive visibility and control over the product lifecycle, establishing a Digital Thread is crucial. This thread connects all relevant information and data across various business functions, products, and lifecycles, enabling seamless, real-time insights for better decision-making and enhanced collaboration.

The Digital Thread connects data across functional silos and enables business collaboration through enterprise platforms like PDM/PLM, ERP, MRP, MES, CRM, SCM, ALM, and other IT/OT tools and technologies.

Connecting Digital TwinsBy connecting enterprise platforms, organizations can gain a holistic view of their product lifecycle, from concept development to retirement, and ensure that all relevant stakeholders have access to the same accurate and up-to-date information. This enables them to make informed decisions, improve collaboration, reduce errors and delays, and ultimately, improve their overall business performance.

To attain comprehensive visibility and control over the product lifecycle, establishing a Digital Thread is essential. This thread links all relevant information and data across various business functions, products, and lifecycles.

To successfully deliver value from Digital Twins and other digital assets, a holistic approach is necessary that includes business change, lean operations, pragmatic delivery, and continuous improvement. This approach should be implemented throughout the entire lifecycle of the digital asset, from the strategic initiative stage to business-as-usual maintenance and support.

Robust Business Change

Robust change business case leadership and ongoing maintenance throughout benefit realization

Lean Operations

Lean and effective implementation governance, data and people focused deployment; stakeholder management

Pragmatic Delivery

Technical delivery management; vendor and third party performance coordination; operations and PMO

Continuous Improvement

Continuous client requirement alignment with leadership of solution architecture and technical deployment

A Digital Twin is a conceptual model representing an equivalent digital replica of a physical object or future asset, driving innovation, streamlined developments and operations throughout their lifecycle.

Data-driven organisation: navigating the connected data thread

The transformation towards digitalization can bring significant benefits to organizations, but requires a shift in mindset, processes, and technology. This change must be carried out in a lean and pragmatic manner, with a focus on delivering value to the customer while minimizing waste and maximizing efficiency.

In addition, it is essential to continuously improve upon the digital asset, including the Digital Twin, through regular maintenance, support, and upgrades. This approach ensures that the digital asset remains relevant and continues to provide value to the organization over its entire lifecycle.

Let's talkDigital Twins are virtual representations of physical objects or systems that coexist throughout the product development and operation phases. These models can take many forms, from CAD and CAE to non-geometric data and mathematical models. Additionally, they can be used for a variety of purposes, such as product concept development, launch, and operations, and can even include predictive twins that model future states and behaviors.

As the technology evolves, Digital Twins are becoming increasingly important in the context of the Internet of Things, Artificial Intelligence, and data analytics. By incorporating data from multiple sources, digital platforms can optimize operational performance, facilitate collaboration, support scenario planning, and enable effective simulations.

However, realizing the full potential of Digital Twins requires a combination of business change, lean operations, pragmatic delivery, and continuous improvement. This means transitioning from a strategic initiative to business-as-usual maintenance and support, and continually refining and enhancing the models over time.

Development

In order to align initial virtual twins with carry-over product strategies, concepts are designed using virtual models based on product and platform, such as cost models, market and technical attributes, CAD carry-over, make or buy strategy, technology benchmarking, virtual product definition, cost base, and virtual build requirements.

Launch

The alignment of initial virtual twins with carry-over product strategies involves designing concepts with virtual models based on product and platform, including cost models, concept BOM, market and technical attributes, CAD carry-over, make or buy strategy, technology benchmarking, virtual product definition, cost base, and virtual build requirements.

Operations

To provide continuous service through in-field operational Digital Twins, connected products are optimized for shelf life extension, embedded software is monitored and updated on-air, asset performance is optimized using machine learning, and IOT, big data, and AI are leveraged to extend the product lifecycle.

In the operations phase, Digital Twins utilize IoT and connectivity to enhance product usage and maintenance, improving customer experience while minimizing disruption. During concept development and industrialization, leading to market launch, they simulate a product's behavior, offering insights for optimization before production. Scope and complexity vary based on the domain and product lifecycle stage.

Industry insights: data continuity and digital transformation

virtual+digital: the blog